Heat is one of the most destructive forces affecting paint performance, yet it’s often overlooked until costly failures occur. Whether you’re a professional contractor facing warranty claims or a homeowner dealing with peeling paint after a scorching summer, understanding how temperature impacts paint chemistry is crucial for achieving lasting, professional results.

Every year, heat-related paint failures cost the industry millions of dollars in repairs, re-work, and warranty claims. More importantly, these failures are largely preventable with proper knowledge and planning. This comprehensive guide will help you understand the science behind heat damage, recognize the warning signs, and implement proven strategies to protect your paint investments.

The Science: How Temperature Impacts Paint Chemistry

The Role of Molecular Movement in Paint Curing

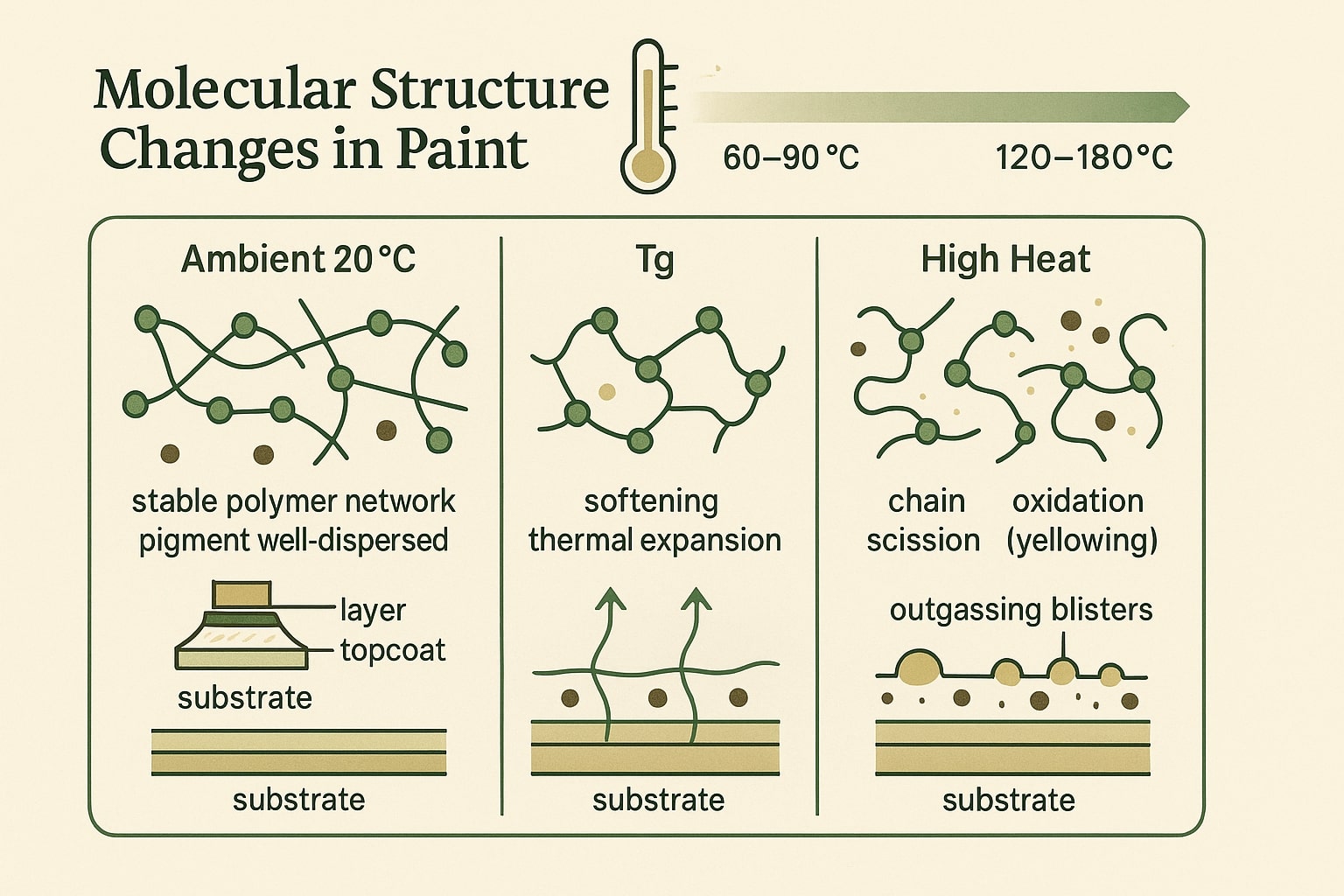

Paint curing is fundamentally a chemical process where liquid components transform into a solid, protective film. Heat dramatically accelerates molecular movement within the paint film, disrupting this carefully balanced process. When temperatures rise above optimal ranges, solvents evaporate too quickly, preventing proper flow and leveling. This rapid solvent loss traps imperfections in the film and creates weak points that lead to premature failure.

Thermal expansion and contraction create additional stress on paint films. As substrates heat up during the day and cool at night, they expand and contract at different rates than the paint film. This differential movement creates internal stress that can cause cracking, delamination, and adhesion loss over time. The effect is particularly pronounced on metal substrates, which can expand significantly more than organic coatings.

Critical Temperature Thresholds for Different Paint Types

Understanding temperature limits for different paint formulations is essential for preventing heat-related failures. Latex paints perform optimally between 50-85°F, with most manufacturers recommending against application above 85°F. Beyond this threshold, water evaporates too rapidly, preventing proper coalescence of the latex particles and resulting in poor film formation.

Oil-based paints have a slightly wider working window of 40-90°F, but they’re not immune to heat damage. High temperatures cause thinning that leads to brush marks, sags, and uneven coverage. The oxidative curing process of oil-based paints is also accelerated by heat, potentially causing the surface to skin over before underlying layers have properly cured.

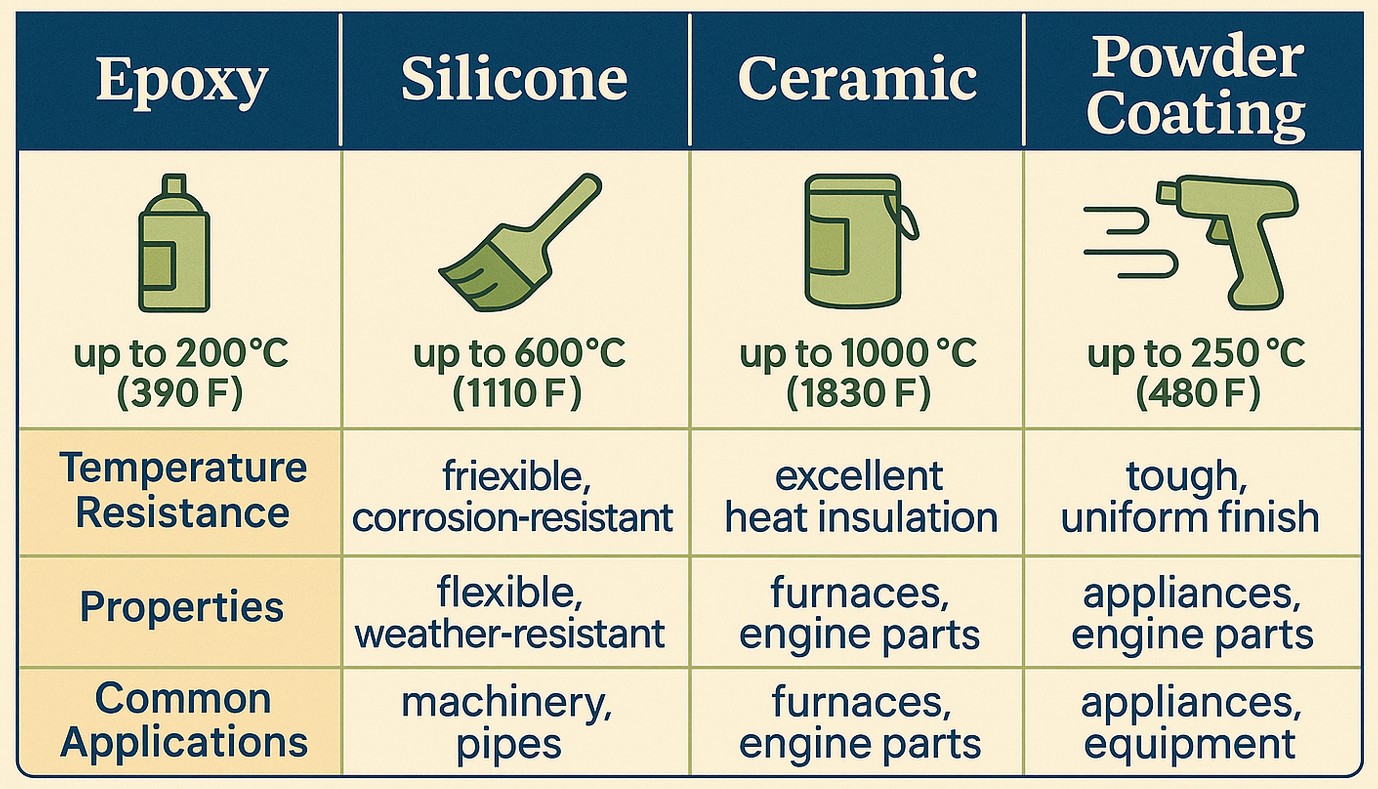

Specialty high-temperature coatings are formulated to withstand extreme conditions, with some silicone-based systems rated for continuous exposure up to 1200°F. However, even these specialized products have application temperature limits, typically requiring substrate temperatures below 150°F during application for proper adhesion.

| Paint Type | Typical Tg (°C) | Usable Temperature Range (°C) | Degradation Onset (°C) | Notes |

|---|---|---|---|---|

| Acrylic (thermoplastic) | 40–100 | –10 to 80 | 120–150 | Good UV resistance, but softens above Tg. |

| Epoxy (thermoset) | 90–150 | –40 to 120 | 180–200 | Excellent adhesion, chalking at high heat. |

| Polyurethane | 60–120 | –20 to 100 | 150–180 | Good chemical resistance, moderate heat stability. |

| Alkyd | 30–80 | –10 to 70 | 120–150 | Yellows easily with heat/oxidation. |

| Silicone-based | 100–200 | –50 to 250 | >300 | High-heat paints, excellent thermal stability. |

| Fluoropolymer (e.g., PVDF) | 70–120 | –40 to 150 | 200–250 | Very high UV/weather resistance, stable at high heat. |

7 Ways Heat Destroys Paint Performance

Adhesion Failure: When Paint Won’t Stick

Heat creates multiple pathways to adhesion failure. Hot substrates cause rapid solvent evaporation, preventing the paint from properly wetting the surface. This poor wetting results in mechanical adhesion problems where the paint sits on top of the substrate rather than bonding to it. The situation is compounded when primers are applied in excessive heat, as they may cure before achieving full penetration into porous substrates.

Surface preparation becomes significantly more challenging in hot conditions. Cleaning solvents evaporate quickly, reducing their effectiveness and potentially leaving residues. Metal surfaces heated by direct sunlight can reach temperatures 30-50°F above air temperature, creating conditions where even heat-resistant primers struggle to achieve proper adhesion.

Rapid Solvent Loss and Film Defects

One of the most visible effects of painting in excessive heat is the formation of brush marks and lap marks. As solvents flash off too quickly, the paint loses its ability to flow and level, freezing surface imperfections in place. This rapid solvent loss also prevents proper edge maintenance, creating visible lap marks where wet paint meets partially dried material.

Orange peel texture is another common heat-related defect, particularly in spray applications. The rapid solvent loss causes the paint droplets to retain their spherical shape rather than flowing together into a smooth film. This texture not only looks unprofessional but also provides more surface area for dirt accumulation and UV exposure.

Thermal Shock and Cracking

Thermal shock occurs when paint films experience rapid temperature changes that exceed their flexibility limits. This is particularly problematic on metal substrates that heat up quickly in direct sunlight and cool rapidly in shade or evening conditions. The repeated expansion and contraction cycles create stress patterns that eventually manifest as cracking, typically in a random or geometric pattern.

Brittle film formation is an insidious heat-related problem that may not become apparent until months after application. When paint cures at excessive temperatures, the polymer chains don’t properly cross-link, resulting in a film that appears normal initially but lacks the flexibility needed for long-term durability. These films are prone to cracking with minor substrate movement or thermal cycling.

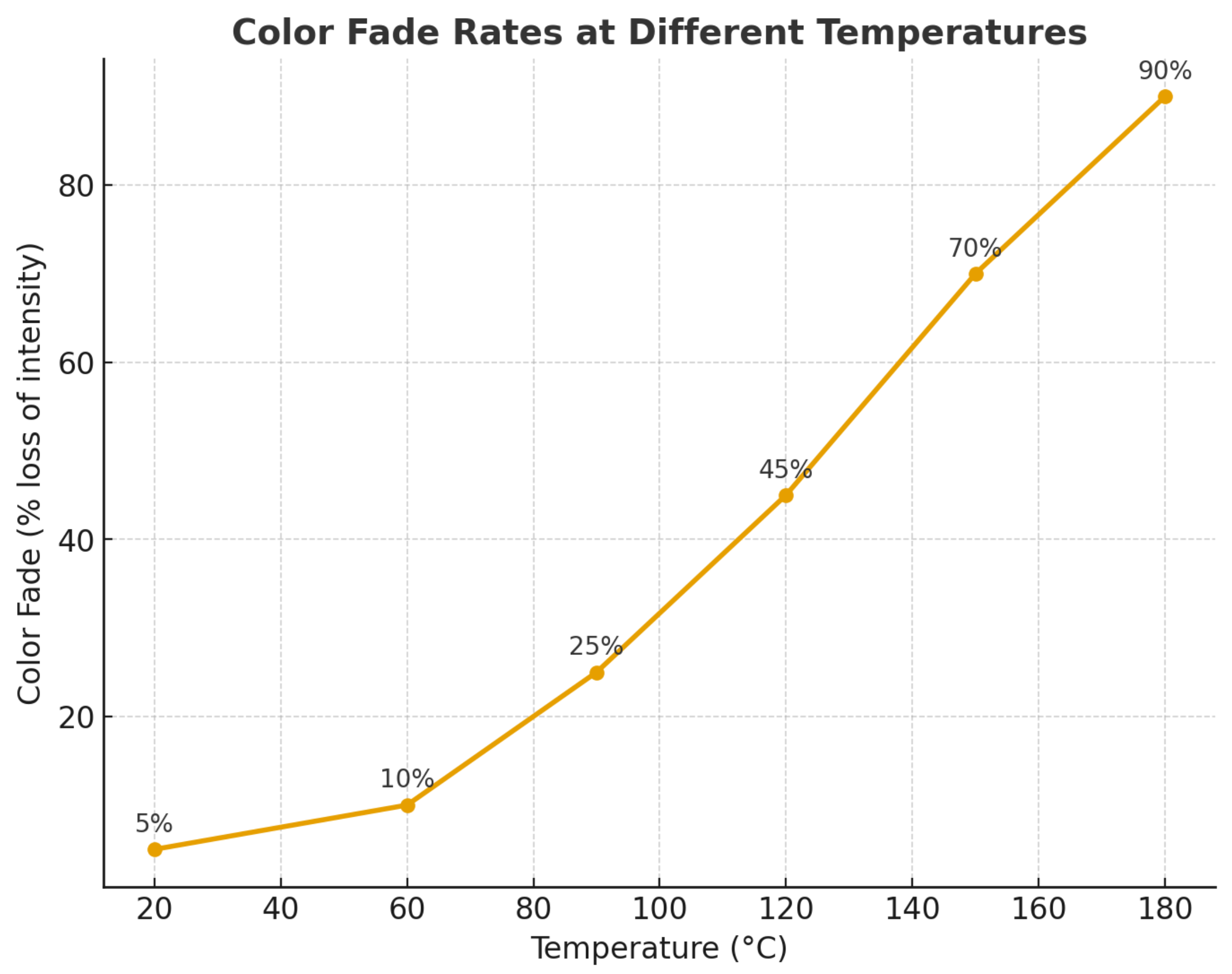

Colour Fading and Chalking Acceleration

Heat dramatically accelerates photodegradation processes, causing colours to fade much faster than expected. The combination of UV radiation and elevated temperatures breaks down pigment molecules and polymer binders, leading to noticeable color shifts within the first year of exposure. Darker colours are particularly susceptible because they absorb more heat, creating a self-perpetuating cycle of degradation.

Chalking, the formation of loose pigment particles on the paint surface, is also accelerated by heat. High temperatures speed up the breakdown of binder resins, releasing pigment particles that create the characteristic chalky residue. This process not only affects appearance but also reduces the paint’s protective properties.

Blistering and Bubbling Formation

Moisture entrapment is a major cause of heat-related paint failures. When paint is applied over surfaces containing moisture, subsequent heating can turn that moisture to steam, creating pressure that pushes the paint film away from the substrate. This problem is particularly common on concrete and wood substrates that may appear dry but contain significant moisture below the surface.

Solvent pop and outgassing create similar visual defects but through different mechanisms. Rapid surface curing in hot conditions can trap solvents beneath the film, which later escape as small bubbles or craters. Porous substrates may also release trapped air when heated, causing similar surface defects.

Premature Aging and Durability Loss

High-temperature exposure accelerates virtually every aging mechanism in paint films. UV degradation, oxidation, hydrolysis, and thermal degradation all proceed faster at elevated temperatures, following the general rule that reaction rates double for every 18°F temperature increase. This means paint exposed to consistently high temperatures may age at two to four times the normal rate.

Reduced lifespan calculations become critical for warranty and maintenance planning. Paint systems designed for 10-year service life in temperate climates may only last 3-5 years in hot, sunny environments without proper product selection and application techniques.

Application Problems: When Paint Becomes Unworkable

Viscosity changes in hot weather make paint application challenging even when other conditions seem acceptable. Thinning paint flows too easily, causing drips and sags, while thickening paint (paradoxically common with some latex formulations) becomes difficult to spread evenly. These viscosity changes also affect coverage rates, potentially leaving areas under-coated.

Flash time reduction is another critical application issue in hot weather. The working time between application and tool marking decreases dramatically, forcing painters to work in smaller sections and potentially creating more lap marks and surface defects. This shortened working time also increases labour costs and stress on painting crews.

Substrate-Specific Heat Challenges

Metal Surfaces: Extreme Heat Absorption

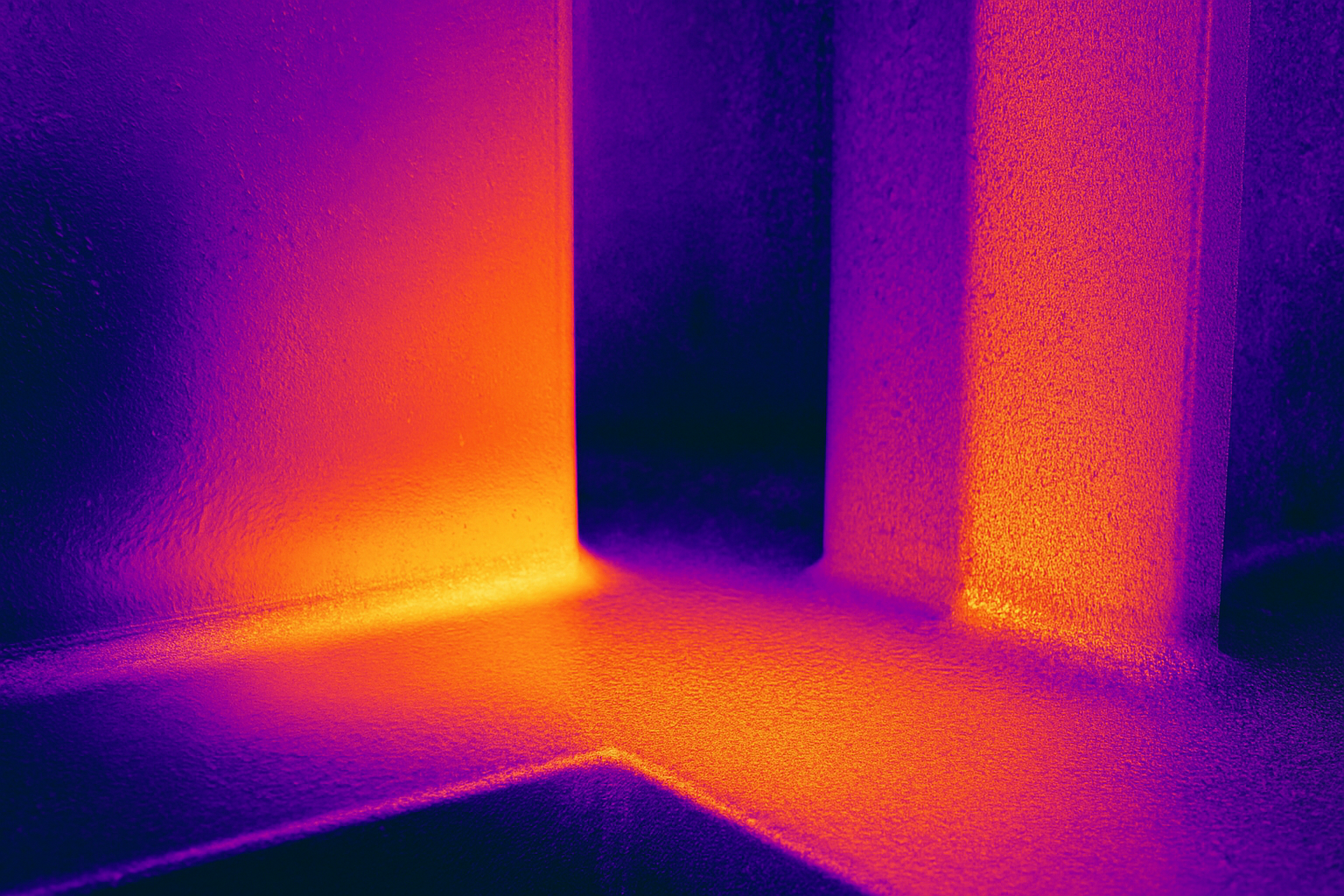

Metal substrates present unique challenges in hot weather due to their excellent thermal conductivity and high heat capacity. Dark-colored metals can reach surface temperatures exceeding 150°F in direct sunlight, well beyond the application limits of most paints. Even light-colored metals can become too hot for proper paint application during peak sun hours.

Thermal bridging considerations become important for metal structures with complex geometries. Areas where thin metal sections connect to thicker masses can experience rapid temperature fluctuations that stress paint films. Expansion joints and connections are particularly vulnerable to heat-related paint failures.

Concrete and Masonry: Thermal Mass Effects

Concrete and masonry substrates have high thermal mass, meaning they absorb heat during the day and release it slowly at night. This characteristic can extend high-temperature conditions well into evening hours, limiting painting windows more than air temperature alone would suggest. Surface temperatures of concrete can remain elevated for hours after air temperatures drop to acceptable levels.

Heat retention also affects moisture migration in concrete substrates. Heating drives moisture deeper into the concrete during the day, but as temperatures drop, this moisture can migrate back to the surface, potentially causing adhesion problems with recently applied paint. This moisture movement is often invisible but can lead to paint failures weeks or months after application.

Wood Substrates: Expansion and Resin Bleeding

Wood substrates experience significant dimensional changes with temperature fluctuations, particularly across the grain. These movements can stress paint films and cause cracking at joints and connections. Grain raising is also accelerated in hot, humid conditions as surface fibres expand and lift, creating a rough surface that telegraphs through thin paint films.

Tannin bleed acceleration is a particular problem with certain wood species in hot weather. Heat mobilizes water-soluble extractives, causing them to migrate through the paint film and create unsightly staining. This problem is most severe on cedar, redwood, and oak, particularly when these woods are exposed to direct sunlight during and after painting.

Environmental Factors Beyond Air Temperature

Surface Temperature vs. Air Temperature

One of the most critical concepts for hot weather painting is understanding the difference between air temperature and surface temperature. While weather reports provide air temperature measured in shade, actual substrate temperatures can be significantly higher. Dark surfaces in direct sunlight commonly reach temperatures 30-50°F above air temperature, and metal surfaces can be even hotter.

Measuring actual substrate temperature requires an infrared thermometer or contact thermometer. These tools should be standard equipment for any painting crew working in hot climates. Surface temperature measurements should be taken in multiple locations and at different times to understand temperature patterns across the project area.

Humidity’s Role in Heat-Related Paint Problems

Relative humidity has a complex relationship with temperature that significantly affects paint performance. High humidity slows solvent evaporation, which can be beneficial in hot weather by extending working time. However, high humidity also slows water evaporation from latex paints, potentially causing extended cure times and increased susceptibility to early rain damage.

Dew point considerations become critical for hot weather painting, particularly for early morning and late evening work. When surface temperatures drop below the dew point, moisture condenses on the surface, preventing proper paint adhesion. This is particularly problematic on metal substrates that cool quickly after sunset.

Wind, Sun Exposure, and Microclimate Effects

Wind can be both beneficial and harmful in hot weather painting. Light air movement helps control surface temperatures and extends working time by carrying away heat and solvents. However, strong winds can cause excessive solvent loss, leading to spray drift and rapid skinning of the paint surface.

Creating shade for painting projects is often the most effective way to manage heat problems. Temporary shade structures can reduce surface temperatures by 20-30°F, bringing conditions back into acceptable ranges. Professional painting crews often use tent systems or schedule work to follow natural shade patterns around buildings.

Recommended Painting Conditions Matrix

| Condition | Recommended Range | Notes / Considerations |

|---|---|---|

| Ambient Temperature | 10–30 °C (50–86 °F) | Avoid below 5 °C (curing slows) or above 35 °C (solvent flash-off, poor leveling). |

| Surface Temperature | At least 3 °C above dew point | Prevents condensation that causes adhesion failure. |

| Relative Humidity (RH) | 40–70% | Too high (>80%) risks blushing, poor curing; too low (<30%) may cause fast drying and cracking. |

| Dew Point Margin | ≥ 3 °C | Ensures surface stays dry during painting. |

| Airflow / Ventilation | Moderate, not direct draft | Required for solvent evaporation, but strong drafts cause defects. |

| Substrate Cleanliness | Free of dust, oil, grease, rust | Surface prep critical for adhesion and durability. |

| Coating Thickness | As specified by manufacturer | Apply within recommended wet/dry film thickness. |

Heat-Resistant Paint Technologies and Solutions

High-Temperature Paint Formulations

Modern paint technology offers several specialized formulations for high-temperature applications. Silicone-based coatings provide excellent heat resistance up to 1200°F while maintaining flexibility and color retention. These systems cure through moisture reaction rather than solvent evaporation, making them less sensitive to application temperature conditions.

Ceramic and aluminum-filled paints offer both heat resistance and reflective properties. The ceramic particles provide thermal barriers while aluminum flakes reflect radiant heat away from the substrate. These specialized formulations are particularly valuable for industrial applications, metal roofing, and automotive exhaust systems.

Intumescent coatings represent the ultimate in fire protection, expanding when heated to form insulating char layers. While primarily used for structural fire protection, these coatings also provide excellent heat resistance for normal operating conditions.

Reflective and Cool Roof Coatings

Solar reflectance index (SRI) ratings have become increasingly important as building codes emphasize energy efficiency. High-SRI coatings can reduce surface temperatures by 30-50°F compared to conventional dark coatings, dramatically extending paint life and reducing cooling costs.

Energy savings calculations show that reflective roof coatings typically pay for themselves within 2-5 years through reduced air conditioning costs. The additional benefit of extended coating life makes these systems highly cost-effective for commercial and residential applications in hot climates.

Primer Selection for Hot Climate Applications

Heat-activated bonding primers represent a newer technology that actually improves adhesion at elevated temperatures. These systems use thermal energy to activate chemical bonding mechanisms, making them ideal for metal substrates in hot climates.

Thermal barrier primer systems create insulating layers that protect topcoats from substrate heat. These specialized primers are particularly valuable for metal roofing and industrial applications where substrate temperatures regularly exceed normal paint limits.

Practical Strategies for Hot Weather Painting

Timing Your Paint Project

Successful hot weather painting starts with intelligent scheduling. Early morning painting, starting before sunrise, takes advantage of the coolest surface temperatures and highest humidity levels of the day. Most hot climate painters start work between 5:00 and 6:00 AM, working until surface temperatures exceed acceptable limits.

Late evening painting can also be effective, but dew point considerations become critical. Painters must stop work with enough time for the paint to develop sufficient cure before dew formation. This typically means stopping work 2-3 hours before sunset, depending on local climate conditions.

Seasonal planning for hot climates involves concentrating exterior work during cooler months when possible. Many professional contractors in desert regions do the majority of their exterior work between November and March, focusing on interior projects during summer months.

Surface Preparation in Hot Weather

Cooling techniques for hot substrates can extend working windows and improve results. Water misting systems can reduce surface temperatures by 15-20°F, though care must be taken to ensure complete drying before paint application. Some contractors use ice water in pressure washers for cleaning hot metal surfaces.

Modified cleaning procedures may be necessary in extreme heat. Solvent cleaners evaporate quickly, reducing their effectiveness and potentially leaving residues. Using cooler solvents, working in smaller sections, and increasing cleaning frequency can maintain preparation quality in hot conditions.

Application Technique Modifications

Brush and roller techniques must be adapted for hot weather conditions. Shorter brush strokes, more frequent tool cleaning, and constant attention to wet edges become essential. Many painters switch to higher-quality brushes that hold more paint and maintain better edge control in challenging conditions.

Spray application requires particular attention to gun settings and material flow rates. Reduced air pressure, increased fluid flow, and closer working distances help compensate for rapid solvent loss. Electrostatic spray systems can be particularly challenging in hot, dry conditions due to increased static electricity buildup.

Creating Shade and Controlling Temperature

Temporary shade structures range from simple tarps to sophisticated tent systems designed specifically for painting applications. Professional-grade shade systems can reduce surface temperatures by 20-30°F while providing wind protection and improving working conditions for painting crews.

Misting systems and cooling methods can provide additional temperature control. Evaporative cooling systems work particularly well in dry climates, while direct substrate cooling with water or ice can bring surface temperatures into acceptable ranges.

When NOT to Paint: Critical Temperature Guidelines

Absolute Temperature Limits by Paint Type

Manufacturer specifications provide the definitive guidance for temperature limits, but these are often conservative and may not account for all real-world conditions. Most latex paints specify maximum application temperatures of 85-90°F, while oil-based products may allow slightly higher temperatures.

Warranty considerations make following manufacturer guidelines critically important. Paint failures due to application outside specified temperature ranges typically void product warranties, leaving contractors liable for expensive repairs and replacements.

Recognizing Dangerous Painting Conditions

Heat index calculations combine temperature and humidity to assess the total thermal stress on both paint and painters. Heat index values above 90°F significantly increase the risk of paint application problems, while values above 105°F create dangerous conditions for workers.

Worker safety temperature thresholds must always take precedence over project schedules. OSHA guidelines for hot weather work include mandatory rest periods, hydration requirements, and work restrictions when heat index values exceed safe levels.

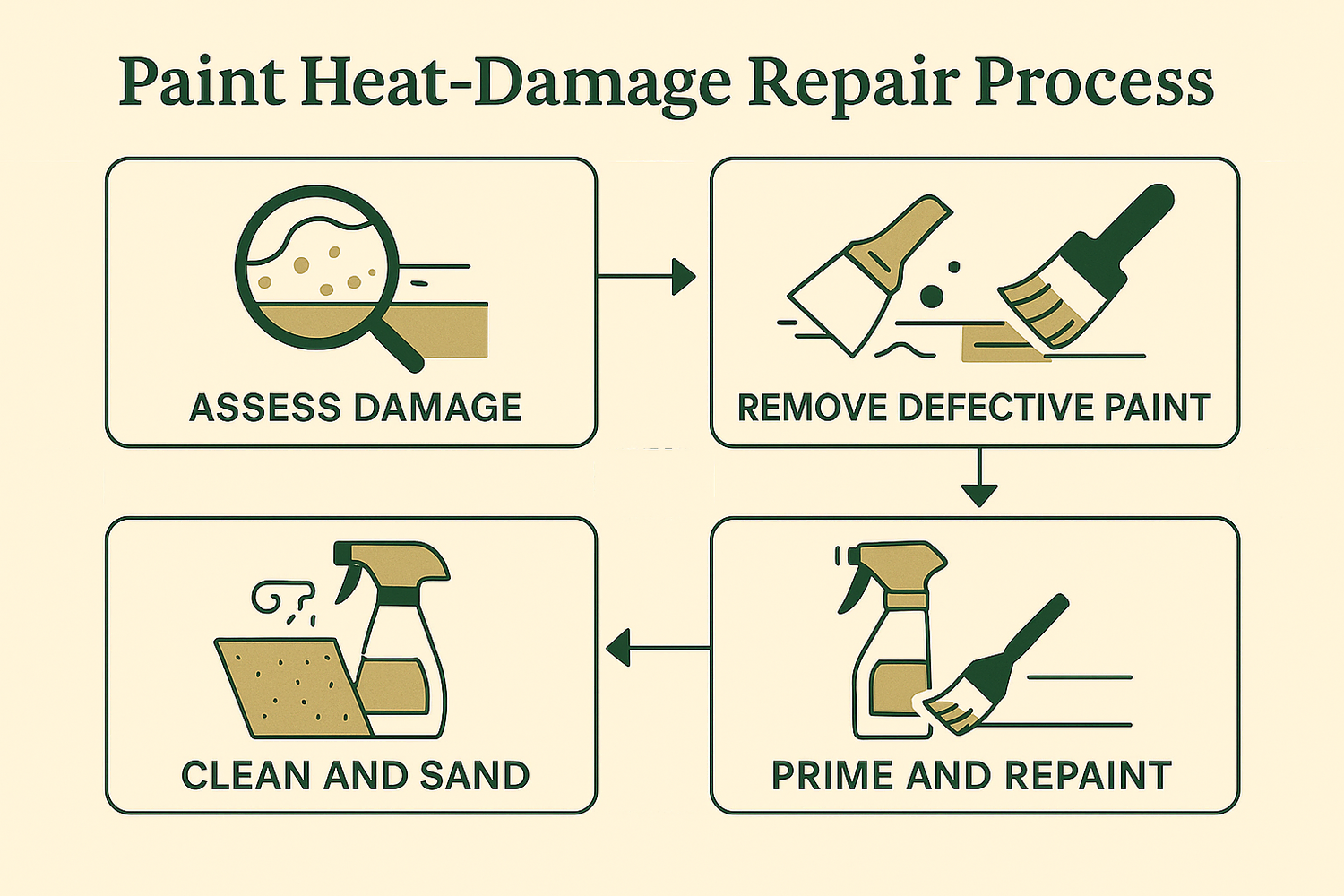

Troubleshooting and Repairing Heat-Damaged Paint

Diagnosing Heat vs. Other Paint Failures

Visual identification of heat damage requires understanding the characteristic patterns of thermal stress. Heat-related cracking typically appears as random or geometric patterns, while moisture-related failures show more linear crack patterns following surface irregularities.

Professional diagnosis may be necessary for complex failure patterns or when warranty claims are involved. Paint failure analysis can identify the specific mechanisms involved and help prevent similar problems in future applications.

Repair Strategies for Heat-Damaged Surfaces

Localized repair techniques can address minor heat damage without full system replacement. Crack sealing, spot priming, and selective recoating can extend the life of heat-damaged systems when properly executed.

Full system replacement becomes necessary when heat damage is extensive or when underlying adhesion has been compromised. These situations require complete removal of failed coatings and proper surface preparation before recoating.

Preventing Future Heat Damage

Long-term protection strategies focus on product selection, application timing, and ongoing maintenance. Choosing appropriate paint systems for local climate conditions and following proper application procedures can prevent most heat-related failures.

Maintenance scheduling for hot climates typically requires more frequent inspections and touch-up work than temperate regions. Early intervention can address minor problems before they become major failures requiring complete recoating.

Cost Analysis: Heat Damage Prevention vs. Repair

Economic Impact of Heat-Related Paint Failures

Industry statistics show that heat-related paint failures cost commercial building owners an average of $2-5 per square foot in repairs and replacement coatings. For residential applications, premature paint failure can cost homeowners $3,000-10,000 for a typical house re-paint.

Return on investment calculations for prevention measures consistently show positive results. Spending 20-30% more on appropriate paint systems and proper application techniques typically saves 200-400% in avoided repair costs over a 10-year period.

Paint Heat Damage Prevention vs. Repair Costs (Metro Vancouver estimates, CAD)

| Surface / Issue | Prevention (what to do) | Estimated prevention cost* | If heat damage occurs… (typical fix) | Estimated repair cost* | Multiplier (repair ÷ prevention) |

|---|---|---|---|---|---|

| South/West-facing siding (wood/fiber-cement) | Use light/IR-reflective colours, spot-prime bare areas, 2 UV-resistant topcoats | $1,200–$2,500 per 1,000 sq ft of wall area | Replace 5–10% failed boards, patch, full-elevation repaint | $5,000–$12,000 per 1,000 sq ft | 3–6× |

| Stucco façades | High-build UV acrylic or elastomeric coat; maintain caulks | $2,000–$3,500 per 1,000 sq ft | Route/fill cracks, texture-match, full repaint | $4,000–$7,000 per 1,000 sq ft | 2–4× |

| Wood trim & fascia | Seal end-grain, prime knots, UV-stable enamel; maintain joints | $600–$1,200 per 200 linear ft | Replace rotten sections (10–30%), sand/prime, repaint | $1,800–$4,000 per 200 linear ft | 3–5× |

| Entry & garage doors | Light-reflective colour, UV-rated clear/topcoat; shade where possible | Entry: $250–$600 each • Garage: $400–$900 each | Strip/refinish (wood) or panel repair; repaint hardware | Entry: $800–$1,800 • Garage: $1,200–$3,000 (replacement can be $2,000–$6,000+) | 4–10× |

| Metal railings & gates | Rust-inhibiting primer + UV topcoat; touch-ups on nicks | $300–$700 per 40 linear ft | Rust removal, spot-weld/metal repair, prime, repaint | $900–$2,000 per 40 linear ft | 2–4× |

| Window/door perimeters | UV-rated elastomeric caulk, paint over seals | $200–$450 per 10 openings | Substrate repair from water ingress, re-seal, repaint | $800–$2,500 per 10 openings | 4–12× |

| Decks & exterior stairs † | Re-coat with UV oil/solid stain every 2–3 yrs | $600–$1,200 per 200 sq ft | Board replacement, sanding, restain | $1,500–$3,500 per 200 sq ft | 2–5× |

* Estimates include labour + materials, typical access, and standard prep. GST not included. Actuals vary with condition, height/access, detailing, and colour changes.

† Informational only: decks/steps are excluded from the workmanship warranty.

Hemlock Painting: We warranty our work for 3 years on all surfaces except floors, steps, and decks (these are excluded from warranty). Interior projects have a minimum job value of $1,400 + GST; exterior projects have a minimum of $2,400 + GST. For a site-specific quote, hit Book Estimate and we’ll tailor numbers to your home.

Warranty Considerations and Insurance Claims

Paint manufacturer warranties typically exclude coverage for application outside specified temperature ranges, making proper documentation of application conditions essential. Contractors should maintain temperature logs and surface temperature measurements for all projects in hot climates.

Insurance claims for heat-related paint damage often hinge on whether proper procedures were followed during application. Documentation of appropriate product selection, surface preparation, and application conditions can make the difference between covered and excluded claims.

Professional Best Practices and Industry Standards

PDCA and Industry Guidelines for Hot Weather Painting

The Painting and Decorating Contractors of America (PDCA) provides specific guidelines for hot weather painting that have become industry standards. These recommendations cover temperature limits, application procedures, and quality control measures for extreme weather conditions.

Professional association recommendations emphasize the importance of job site documentation, crew training, and appropriate equipment for hot weather work. Following these guidelines helps protect both contractors and property owners from heat-related failures.

Equipment and Tool Considerations

Heat-resistant application tools become essential for hot weather work. Brushes with synthetic bristles, rollers with heat-resistant cores, and spray equipment designed for high-temperature applications perform better and last longer in extreme conditions.

Temperature monitoring equipment should include both air temperature and surface temperature measurement capabilities. Infrared thermometers, heat index calculators, and recording thermometers help painting crews make informed decisions about when conditions are acceptable for work.

Conclusion

Understanding how heat affects paint performance is essential for achieving professional, long-lasting results in today’s challenging climate conditions. From the molecular level changes that occur in paint films to the practical application techniques that can overcome high-temperature challenges, knowledge is the key to success.

The investment in proper education, equipment, and materials for hot weather painting pays dividends through reduced callbacks, improved customer satisfaction, and protection of professional reputation. As climate change continues to create more extreme weather conditions, the ability to work successfully in high temperatures becomes increasingly valuable for painting professionals.

By implementing the strategies outlined in this guide—from choosing appropriate paint systems to timing application work and creating proper environmental controls—painters can achieve excellent results even in challenging hot weather conditions. The key is respecting the science behind paint chemistry while applying practical solutions that address real-world challenges.

Remember that when in doubt, it’s always better to delay a project than to compromise quality by working in excessive heat. The short-term inconvenience of rescheduling work is minimal compared to the long-term costs of heat-related paint failures. Professional painters who master hot weather techniques will find themselves with a significant competitive advantage in increasingly hot climates around the world.

Frequently Asked Questions

- Can I paint during a heat wave if I use a heat-resistant primer?

While a heat-resistant primer helps improve adhesion and durability in high temperatures, painting during a heat wave is still not recommended. Extremely high temperatures can cause paint to dry too quickly, leading to blistering, cracking, or poor adhesion. It’s best to paint early in the morning or late in the evening when temperatures are cooler, even with a heat-resistant primer. - How long should I wait after a hot day before painting the next morning?

Wait until early morning temperatures have stabilized and the surface is cool to the touch—usually around sunrise. Surfaces like metal or concrete can retain heat overnight, so you should avoid painting until the temperature is below 85°F (29°C) and the surface has had time to cool. - Will painting in moderate heat void my paint manufacturer’s warranty?

It depends on the specific paint product. Most paint manufacturers provide a recommended temperature range on the label—typically between 50°F (10°C) and 90°F (32°C). If you paint outside this range, including during moderate heat above the limit, it could void the warranty. Always follow the manufacturer’s guidelines closely. - Can I use a paint additive to make regular paint more heat-resistant after application?

Some additives claim to enhance heat resistance, but they rarely match the performance of true heat-resistant or high-temperature paints. These additives may help with thermal expansion or minor resistance but won’t convert standard paint into one suitable for extreme heat. For best results, choose a paint specifically formulated for heat resistance. - How do I calculate the actual cost savings of using expensive heat-resistant paint versus repainting more frequently with standard paint? To calculate cost savings, compare total costs over a defined period (e.g., 10 years):

- Standard Paint: (Initial paint + labor) + (Repaint cost × frequency of repainting)

- Heat-Resistant Paint: (Higher initial paint cost + labour) with less frequent repainting

Then, subtract the long-term cost of heat-resistant paint from the cumulative cost of multiple repaints with standard paint. Also factor in downtime, potential surface damage, and aesthetic degradation in the total cost analysis.